PR 4511 Modbus Communication Enabler Review

The PR 4511 from PR Electronics is a front display for PR Electronics universal transmitters i.e. the PR 4114 universal transmitter that we also use. It transforms the PR 4114 from a signal conditioner into a great versatile data logger, while also acting as a front display menu.

We bought multiple PR 4511 to use in a versatile data logger together with the PR 4114 so we could measure signals from any sensor. I wanted to give my review and experience working with the PR 4511 Modbus communication enabler.

Why We Bought The PR 4511 Modbus Display

The reason we bought the PR4511 Modbus display together with the PR4114 universal transmitter was for its versatility and ease of use. We were looking for a solution that would allow us to monitor and log data from multiple sensors without having to purchase separate displays or data loggers for each sensor type.

The PR 4511 Modbus display, combined with the PR 4114, allows us to connect and measure signals from almost any sensor type, whether it be temperature, pressure, flow, or any other variable. This saved us time and money by providing a one-stop solution for our data logging needs

Modbus RTU is a great communication protocol that is widely used in the industry. The PR 4511 supports Modbus RTU, which allows us to easily connect it to our system and access data from the sensors connected to the PR 4114. This eliminated the need for any additional converters or complicated wiring setups.

First Time Setup and Configuration

Setting up the PR 4511 proved to be straightforward. You simply attach the front display by clicking it onto the PR 4114, after which it functions like a standard display. Here, we could configure the universal transmitter for analog device signals and an output signal as usual.

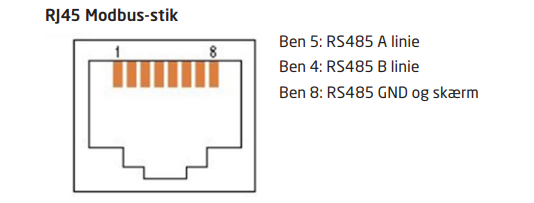

However, configuring the Modbus RTU presented a slightly more challenging task. The Modbus communication line signal is connected via an RJ45 connector, as depicted in the image below from the PR4511 manual.

While one might assume it to be a Modbus network over Modbus TCP, it is, in fact, Modbus RTU.

However, this posed no issue. We simply linked the individual signals to an RS485 converter cable, allowing us to connect the device to our computer via USB.

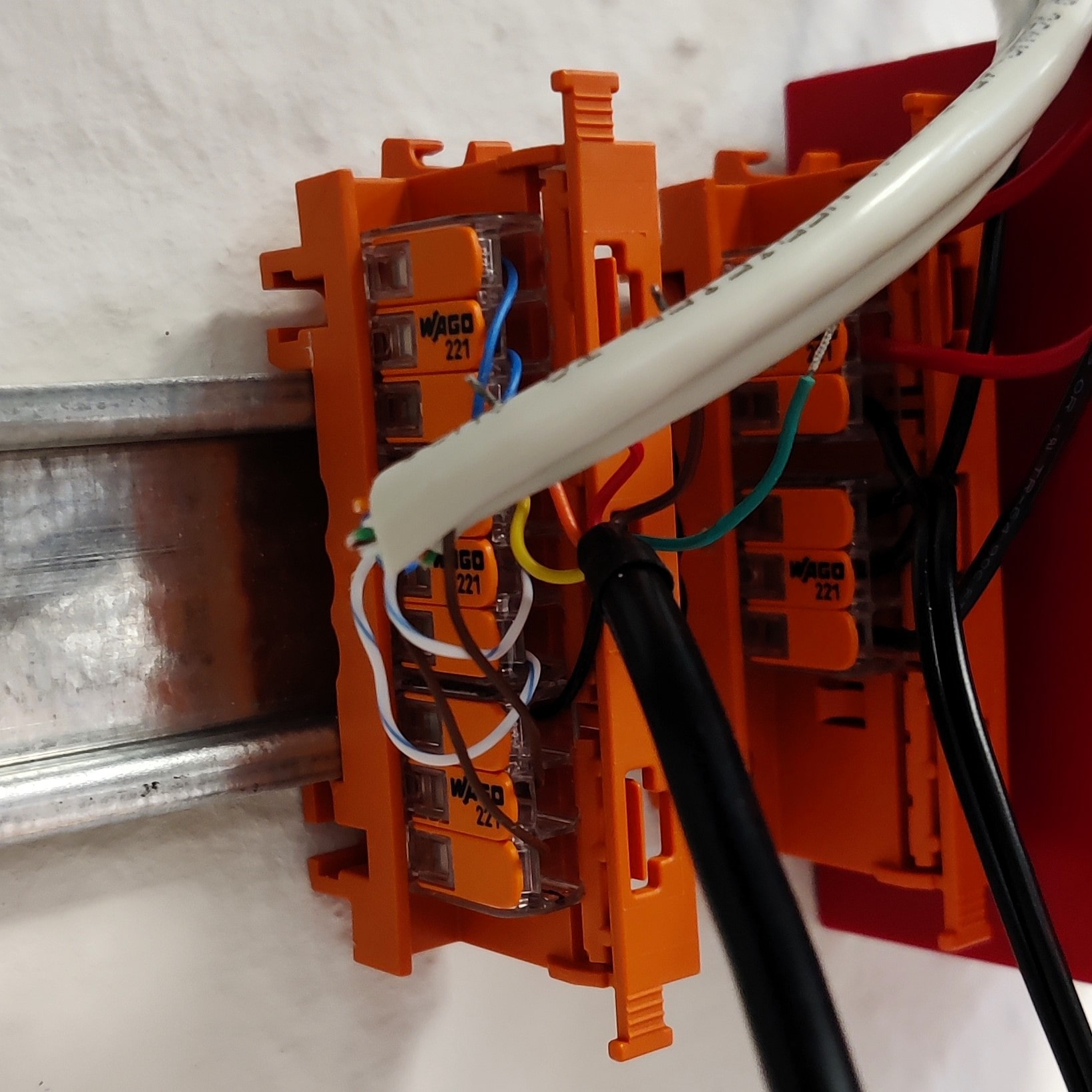

For this simple test we only have two pairs of PR 4114 and PR 4511 so we used some small connectors to connect the two devices together as seen on the picture below. If we however had a wide array of devices then I would probably opt for some of the accessories that PR offers to connect up to eight channels in one cable.

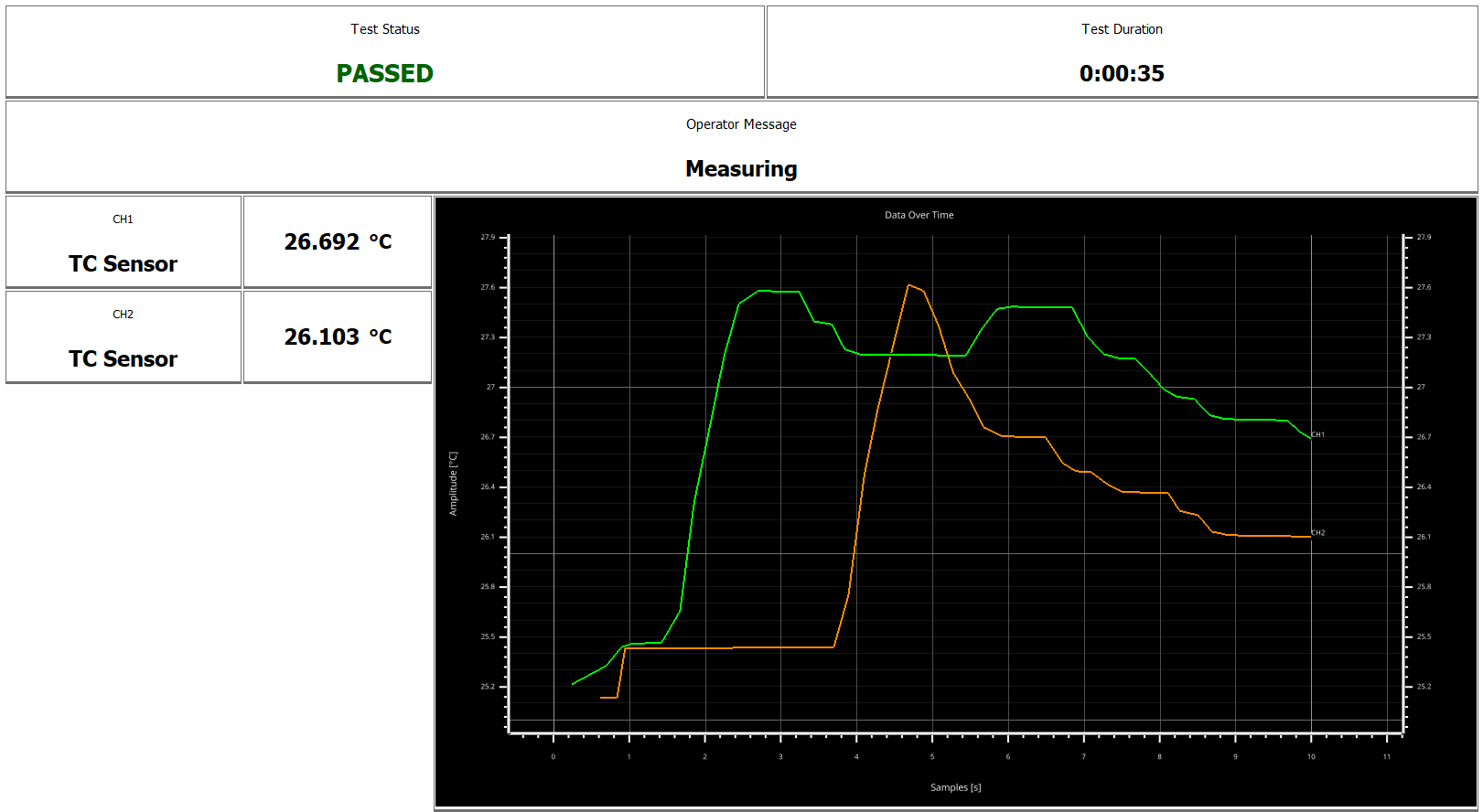

Configuring the client address, baud rate, stop bit, parity bit was easy through the front display menu. We could then access the data from our sensors through our computer using our own test software SAFE.

Measuring With Modbus over PR 4511

To measure correct values over Modbus RTU you need some data processing as dependent on the PR 4114 device settings you need to scale the analog device signals measured.

Here are some examples of where scaling is needed when data logging over Modbus RTU:

- Temperature readings need to be divided by 10 (also stated in the PR 4511 manual).

- Depending on individual unit operating parameters (Display High, Display Low, and Decimal Point) you need to scale the signal coming with 10, 100, or 1000. This is because the front display and Modbus process signal are not synchronized.

An example of this is measuring simple voltage signals between 0 and 10 volts. For the Modbus signal to send the correct value, the PR 4511 device must be configured with the following settings:

- Display High: 0010

- Display Low: 0000

- Decimal Point: XXXX

But maybe I want to have two decimals on the front display. So I configure the PR 4511 as below:

- Display High: 10.00

- Display Low: 00.00

- Decimal Point: XX.XX

Herein lies the problem. My guess is the Modbus value is not synchronized with the decimal point so it reads the the Display High as 1000.

A factor 100 scaling.

So depending on the Decimal Point you need to scale the Modbus value that you read.

This challenge of signal scaling in Modbus communication illustrates the importance of understanding how the PR 4511 and PR 4114 integration translates data, especially for accurate monitoring and data logging purposes.

Fortunately, once we grasped the concept of scaling based on the unit's configuration, we could implement a standard procedure for all our measurements, ensuring the reliability of our data.

The PR 4511 Options We Haven't Talked About

The PR 4511 offers numerous settings that I haven't detailed, which are configurable through Modbus. Essentially, any adjustments possible on the display can also be made via Modbus.

Some of these parameters include:

- Measure Status

- Output Value

- Display Unit

- Display Backlight

The performance of the PR4114 and PR4511 is also pretty good, I could read a Modbus value in about 50 ms per channel. Which for most use cases is plenty fast. Now if you needed a larger number of channels 16+ with sample rates below a second for all channels, then performance might be an issue depending on your setup.

Final Thoughts

Overall, we are extremely satisfied with our purchase of the PR 4511 Modbus display. Its versatility and compatibility with the PR 4114 universal transmitter have made it an essential tool for our data logging needs. Although there was a slight learning curve when it came to configuring the Modbus communication, once we understood the scaling process, it became a seamless part of our data monitoring system.

We highly recommend the PR 4511 to anyone looking for a reliable and efficient Modbus display solution. So far, we haven't encountered any issues or shortcomings with its performance, making it a valuable addition to our instrumentation setup.

Interested in learning more about automating data logging with the PR4114 and our test software SAFE? Schedule a chat with us today and let us show you how it can benefit your testing projects!