What is Data Acquisition

Data acquisition (DAQ) is the process of collecting, measuring, and recording data from various sources. This data can then be used for analysis, monitoring, or control purposes. It is typically used in scientific and industrial applications to gather information about a system or process, e.g. in a performance test or experiment.

In this article, we will describe the basics of what is data acquisition, discuss different data acquisition systems, and why you should choose a data acquisition system.

Now before we begin I need to say that a data acquisition system can be many things. This article will focus on data acquisition systems that are composed of modular systems, and not a single sensor that can send data directly to the cloud.

I would categorize both as a data acquisition system but in this post, we will focus more on a system that consists of several different components.

But let's start with the basics!

Basics of Data Acquisition

The basic principle of data acquisition is to convert physical signals into digital form for processing and storage. This involves four main components: a sensor, a signal conditioner, an analog-to-digital converter (ADC), and a DAQ software.

Sensor

A sensor is a device that detects and measures changes in physical parameters such as temperature, pressure, or light intensity. There are various types of sensors, including mechanical, electrical, and optical sensors.

Examples could be thermocouples, strain gauges, accelerometers, load cells, microphones, etc.

The sensor outputs an analog signal that is proportional to the measured physical quantity.

Signal Conditioning Circuit

The signal conditioning circuitry is responsible for amplifying and filtering the analog signal from the sensor to improve its quality and prepare it for conversion by the ADC. This circuit helps to remove any unwanted noise or distortion and amplify or attenuate the signal if necessary.

Signal conditioning very much depends on the sensor being used, and the type of signal it produces.

For example, some sensors may require excitation voltage or current to operate, while others may produce a very weak signal that needs amplification before being converted.

Some sensors also have this built into their circuitry. E.g if you buy a sensor with 0-10V output this is often the case.

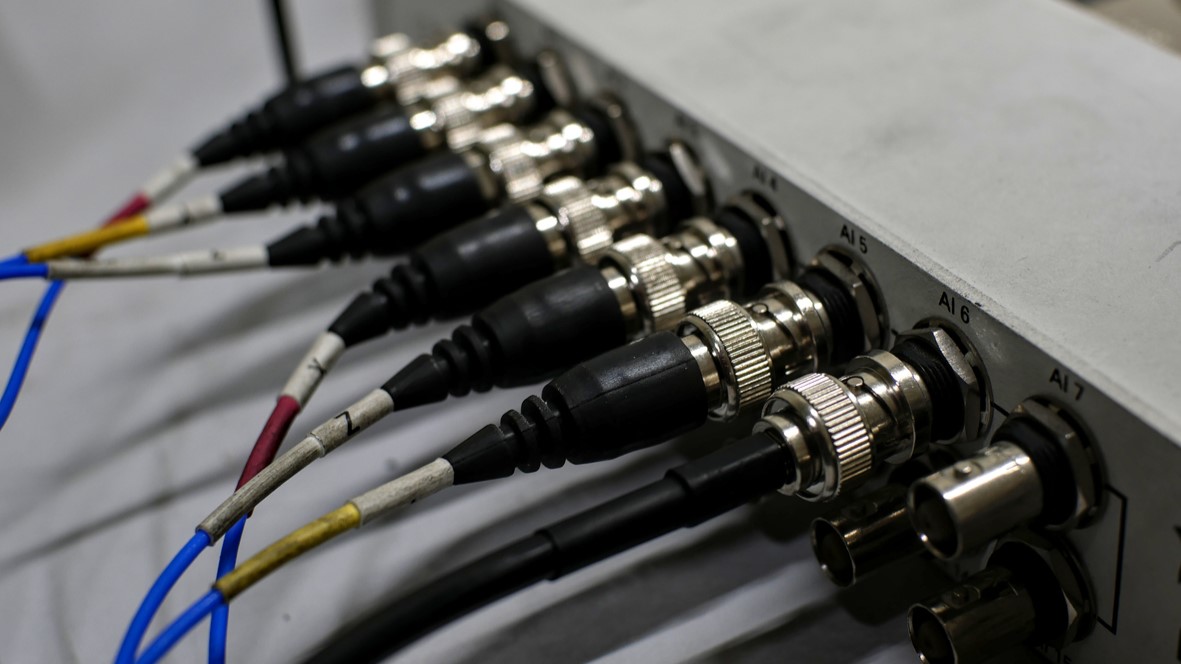

Analog-to-digital converter (ADC)

ADCs converts analog signals from sensors into digital values that can be processed and stored by a computer. It measures the amplitude of the analog signal at discrete intervals and produces corresponding digital values.

ADCs are typically found in DAQ hardware with multiple channels in 2,4,8 channels or more. DAQ hardware with higher channel counts also allows for simultaneous measurement of multiple signals.

The ADC is sometimes also referred to as a data logger and it is typically connected to the PC via USB or Ethernet in some form.

A data acquisition system can also have outputs which are called analog to digital converters (DAC) which is the inverse of ADCs. These convert data in a digital format to an analog signal.

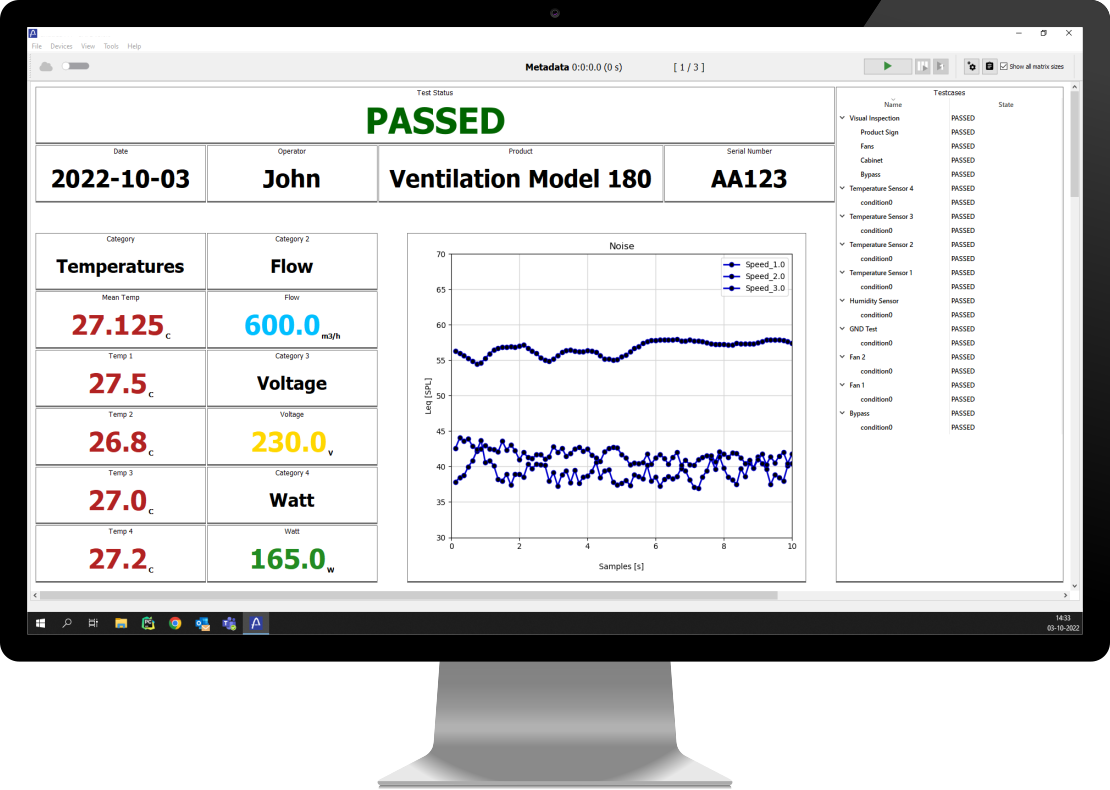

DAQ Software

Data acquisition software is responsible for managing the data acquisition process. It controls the hardware, sets up and configures the channels, collects stores, and displays the acquired data hopefully in a user-friendly format.

The data acquisition software is the heart of the data acquisition system.

There are many types of software. Some software includes various tools for data analysis, visualization, and export to Excel or other formats.

We have developed a state-of-the-art data acquisition software called SAFE that makes it easy to log data with many different data acquisition devices, processing data, and export data without having to write any code.

Examples of Data Acquisition Devices

Now that we understand the basics of data acquisition, let's take a look at some common types of data acquisition devices. I have chosen to focus on some particular devices that are accurate and flexible so you can configure them as you need.

I don't have an affiliation with any of the mentioned products but just good experience and know that these are widely accepted in many different places.

Modular Data Acquisition Systems

Modular DAQ systems are composed of separate modules that can be easily connected to create a customized system. These systems offer flexibility, scalability, and ease of maintenance as individual modules can be replaced if necessary.

I want to mention two examples.

One example is the National Instruments CompactDAQ system which uses a chassis to hold multiple modules such as ADCs and DACs. These modules are connected to the chassis through a bus that carries both power and data signals. The chassis also has a USB or Ethernet connection for communication with the PC.

CompactDAQ has I think have hundreds of modules for pretty much any sensor or input. It's just a great data acquisition device. The downside is that it is on the more costly side.

Another modular data acquisition system is the Helmholz Distributed Fieldbus I/O System which uses fieldbus technology for communication between the modules and the PC. This system also allows for a large number of I/O channels and offers cost-effective solutions

Helmholz is working with e.g. Modbus and other busses as standard which makes it very easy to communicate with. The downside of this system is that it does not have that high of a sample rate but if your application only requires sampling signals in the seconds then this is a perfect way to collect data.

There are many different data loggers and many data acquisition systems you could buy but if you choose any of these two data acquisition systems you are off to a great start in my experience.

Signal Conditioning devices

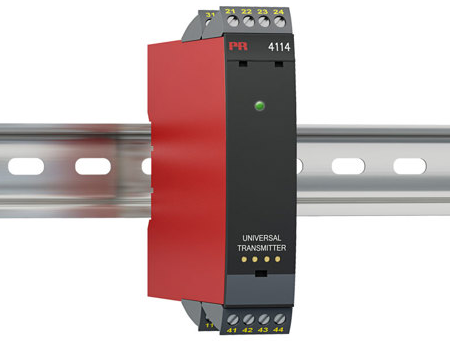

Signal conditioning devices are used to convert and condition signals from sensors into a more usable form for the data acquisition system. One company that has a multitude of different signal conditioners is PR Electronics for example the PR 4114 universal transmitter

This universal transmitter can be set up for different signal conditioning depending on your needs. It can handle signals from temperature, strain gauge, potentiometer, and current loop sensors.

Advantages of Data Acquisition Systems?

There are many reasons to choose a data acquisition system. Some of the key benefits of DAQ systems are written below:

Flexibility

One of the main advantages of a data acquisition system is its flexibility. With modular systems, you can choose the components that best fit your needs and easily add or remove sensors as needed. This allows for customization and scalability based on specific requirements.

Accurate and Reliable Data

With high-quality sensors and signal conditioning, data acquisition systems provide accurate and reliable data that can be used for analysis or decision-making. This is crucial in industries where precise measurements are necessary for safety and performance.

Highly Specific Data Acquisition Applications

Not all data acquisition systems are created equal. There are many different types of sensors and signal conditioning circuits, as well as software options that cater to specific applications. This allows for a more tailored approach to collecting data and ensures the system is optimized for its intended purpose.

Disadvantages of Data Acquisition Systems

There are of course also some downsides to data acquisition systems. Some of the main downsides of a data acquisition system are noted below:

Upfront Cost

Data acquisition systems can be expensive in upfront cost, especially when they require multiple components and have a high channel count. However, the accuracy and reliability of data may justify the cost for industries where precise measurements are vital and can give you an upper hand in performance.

There is no rule of thumb when it comes to cost. There are so many variables that must be taken into account: accuracy, sampling rate, type of sensors, application, etc.

My best guess of an estimate is a minimum of 150 euros per channel plus sensor cost. But it can be much less or much more.

It's just my experience.

System Complexity

With multiple components and software options, data acquisition systems can be complex to set up and maintain. It may require technical expertise and training to properly operate and troubleshoot any issues that may arise.

Especially if you have multiple sensor types and ADCs in your system. You typically need to know about signal paths, calibration, electrical signals, and physical characteristics to get precise measurements and readable and meaningful results.

If you are not sure about how to choose the right data acquisition system or how to set it up. You can always book a meeting with one of our experts here at Encida.

We always want to help you to make great measurements, book a time below.

System Validation

Validating a data acquisition system can be time-consuming and challenging, especially the more complex the DAQ system becomes.

It's crucial to ensure that the system is accurately measuring and recording data before using it for decision-making or analysis. This may require extra testing or calibration procedures.

Applications of a Data Acquisition System

Data acquisition systems have a wide range of applications, from research and development to industrial process control. Below are some common examples of where DAQ systems are used:

Research and Development

In fields such as engineering, science, and medicine, data acquisition systems allow for precise measurement and analysis of various phenomena. This helps researchers to better understand the world around us and develop new

Performance Testing

In industries where performance is critical, such as automotive and aerospace, data acquisition systems are used to measure and analyze various parameters. This allows for optimization and improvement of products or processes.

Quality Control

Data acquisition systems play a vital role in quality control by providing accurate measurements of key process parameters. This can help detect any issues or abnormalities that may affect product quality.

Conclusion

In summary, data acquisition systems have many advantages and applications, but they also come with some challenges.

However, the benefits of accurate and reliable data make them a valuable tool in various industries. With advancements in technology and an ever-growing demand for precise measurements, data acquisition systems will continue to play a crucial role in collecting and analyzing data.

So next time you need to choose a data acquisition system, remember to consider your specific needs and requirements to find the best fit for your application.

Or reach out to me, I am here to help you choose your next data acquisition system for you testing application.