What is a Factory Acceptance Test (FAT)

A Factory Acceptance Test (FAT) is an essential step in the process of designing and producing complex equipment or systems. It is a comprehensive test that ensures the quality, functionality, and safety of the product meets all the customer's requirements before it is delivered and installed on the client's site.

Purpose of a Factory Acceptance Test

The main purpose of a Factory Acceptance Test (FAT) is to verify that the equipment or system meets all specifications and functions as intended. It also serves as a quality assurance measure to identify any potential issues before delivery. This helps prevent delays, additional costs, and customer dissatisfaction.

Who performs a Factory Acceptance Test?

A Factory Acceptance Test is usually performed by the manufacturer's testing team or an independent third-party testing facility hired by the manufacturer. It may also involve representatives from the customer's team to witness and provide feedback on the test.

It is always performed on the manufacturer's site, where the equipment or system is assembled and tested under simulated operating conditions. This allows for any necessary adjustments or modifications to be made before the product is shipped to the customer's site.

Factory Acceptance Testing Protocol

A typical Factory Acceptance Test consists of several components and the testing process can last between a couple of hours or weeks depending on the fat procedure. The testing procedures when doing factory acceptance testing typically include:

Detailed Test Plan

The first step of a Factory Acceptance Test is to develop a detailed test plan that outlines the test objectives, factory acceptance tests, factory acceptance test checklist, factory acceptance test protocol, and acceptance criteria. This plan is usually created by the engineering team in collaboration with the customer to ensure all requirements and performance criteria are met.

Test Environment

The next component involves setting up a suitable test environment, which may include specialized equipment, tools, and software. This environment should closely resemble the intended operating conditions of the equipment or system to ensure accurate testing results.

Safety Testing

Safety should always be a top priority, and the Factory Acceptance Test is no exception. This component involves testing all safety features and protocols to ensure they meet industry standards and regulations. Any safety issues identified during this stage should be addressed before the final product is delivered to the customer.

Functional Testing

During the Factory Acceptance Test, all functional aspects of the equipment or system are thoroughly tested. This includes testing individual components, subsystems, and overall functionality to ensure they work as expected. Any issues that arise during this stage should be addressed and resolved before moving on to the next component.

Performance Testing

Performance testing is a critical component of a Factory Acceptance Test as it verifies the performance and reliability of the equipment or system. This may include stress testing, load testing, and endurance testing to simulate real-world operating conditions. The results from these tests are compared against the acceptance criteria outlined in the test plan.

Alarm Testing

Another important component of a Factory Acceptance Test is alarm testing. This involves testing all alarms and warning systems to ensure they are functioning correctly and can effectively alert operators in case of any issues.

Various Tests and Simulations

The Factory Acceptance Test protocol may include various tests and simulations based on the specific requirements of the equipment or system. These tests can range from environmental testing to software integration testing, depending on the product's complexity.

Documentation Requirements

There is a large documentation requirement for FAT testing. It details test equipment, if the equipment operates correctly, equipment performance, test conducted, etc.

Following the factory acceptance testing, the factory acceptance test checklist is signed and reviewed. The checklist details the test procedure and ideally, presents successful test results. Each test is signed by its performer.

Moreover, the FAT documentation comprises raw data, test results, and a summary report summarizing the testing process's outcomes.

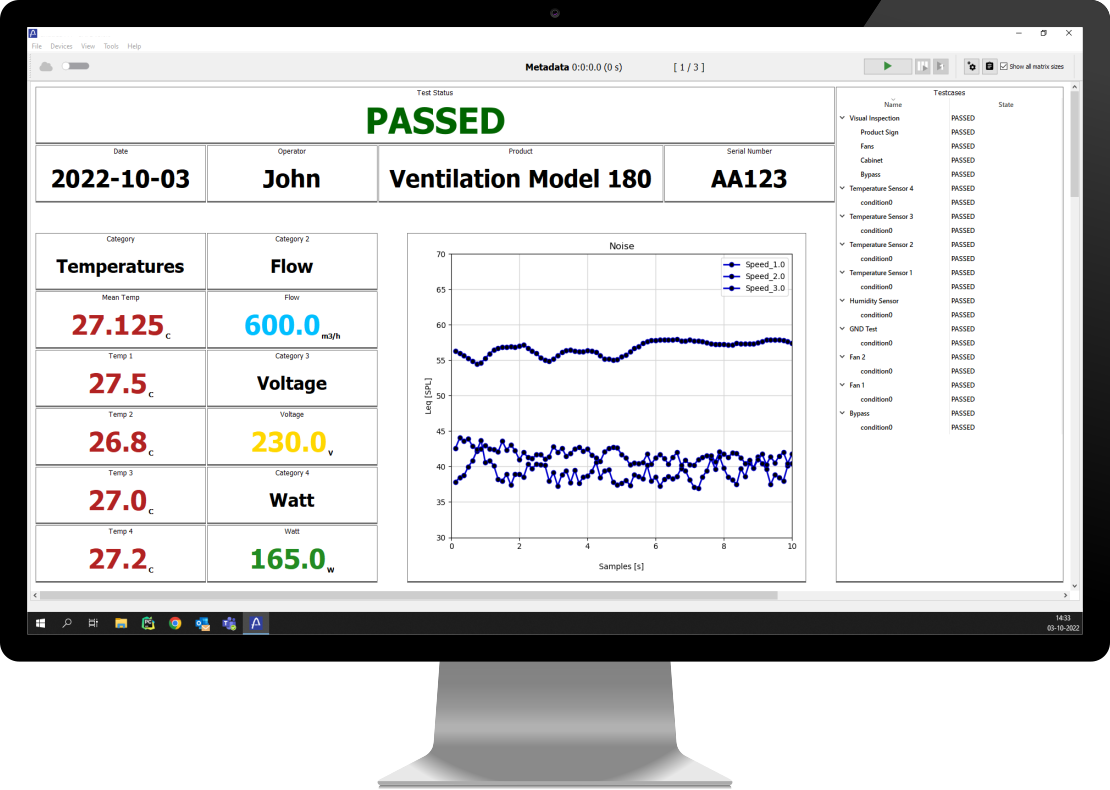

Software for Factory Acceptance Testing

If you don't want to end up with a large paper checklist or a bad Excel sheet not built for FAT testing, then we have the solution.

Our test software SAFE is a no-code solution where you can define your FAT checklist and specified requirements, making it easy for your testers to run the testing process correctly and ensure all tests and results are documented properly. Try it for free now.

Site Acceptance Test (SAT)

People can confuse what is FAT testing and what SAT testing is.

A Site Acceptance Test (SAT) is a similar process to a factory acceptance test (FAT), but it takes place at the customer's site instead of the factory.

The main difference between the site acceptance test and the factory acceptance test is that a FAT focuses on verifying that the product meets the agreed-upon specifications and standards, while SAT focuses on ensuring that it functions correctly in its intended environment after a proper installation.

Another difference between FAT and SAT is their timing. FAT takes place before the product is shipped to the customer, while SAT happens after an adequate factory testing phase, installation, and delivery.

This allows for any necessary adjustments or fixes to be made at the factory, saving time and money compared to finding and fixing issues on-site.

Conclusion

In conclusion, a Factory Acceptance Test is a crucial step in ensuring the quality and functionality of equipment or systems before delivery to customers. It involves several components and thorough testing procedures to verify performance, reliability, and safety.

FAT documentation plays a significant role in recording test results, identifying any issues, and assuring the customer that the equipment meets all specifications and the customer's requirements.